DTC P0011:00 OR P0012:00 [PCM (SKYACTIV-G)]

DTC P0011:00 OR P0012:00 [PCM (SKYACTIV-G)]

SM2334476

id0102t4400000

-

Note

-

• To determine the malfunctioning part, proceed with the diagnostics from “Function Inspection Using M-MDS”.

Details On DTCs

|

Description |

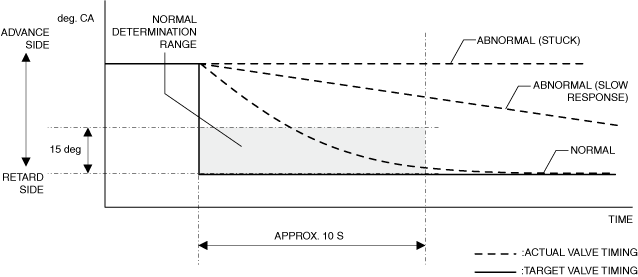

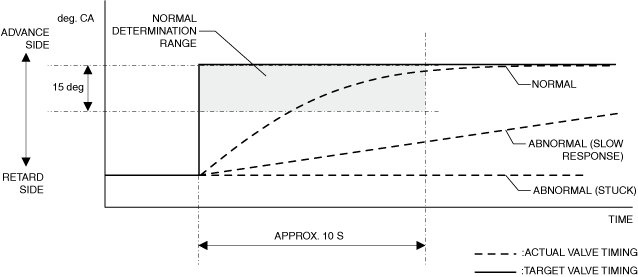

Electric variable valve timing control system: • P0011:00: Over-advanced

• P0012:00: Over-retarded

|

||

|---|---|---|---|

|

Detection condition

|

Determination conditions

|

• P0011:00: For the advance amount from the maximum intake valve retard position, a condition in which the actual advance amount is larger than the target value continues for a specified period of time.

|

|

|

• P0012:00: For the advance amount from the maximum intake valve retard position, a condition in which the actual advance amount is smaller than the target value continues for a specified period of time.

|

|||

|

Preconditions

|

• Battery voltage: above 11 V *1

• Engine speed: 5,000 rpm or less*1

• Engine coolant temperature: 20 °C {68 °F} or more *1

• The following DTCs are not detected:

*1: Standard can be verified by displaying PIDs using M-MDS

|

||

|

Malfunction determination period

|

• 10 s period

|

||

|

Drive cycle

|

• 1

|

||

|

Self test type

|

• CMDTC self test

|

||

|

Sensor used

|

• CKP sensor

• Intake CMP sensor

|

||

|

Fail-safe function

|

• Not applicable

|

||

|

Vehicle status when DTCs are output

|

• Not applicable

|

||

|

Possible cause

|

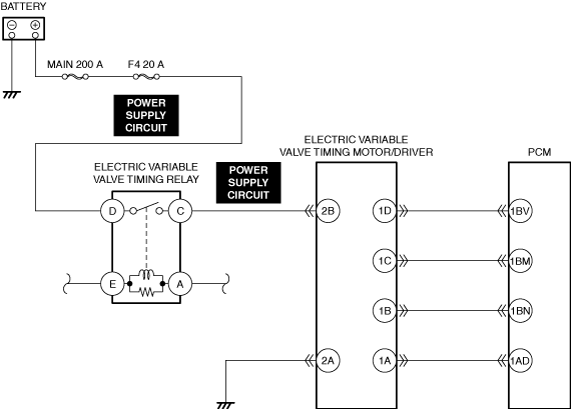

• Electric variable valve timing motor/driver connectors or terminals malfunction

• Short to ground or open circuit in electric variable valve timing relay power supply circuit

• Short to ground in electric variable valve timing motor/driver power supply circuit

• Open circuit in electric variable valve timing motor/driver power supply circuit

• PCM connector or terminals malfunction

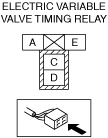

• Electric variable valve timing relay malfunction

• Electric variable valve timing motor malfunction

• Electric variable valve timing actuator malfunction

• Timing chain malfunction

• Mis-detection of intake CMP sensor

• Mis-detection of CKP sensor

• PCM malfunction

|

||

|

|||

|

|

||

|

|||

|

|||

Function Explanation (DTC Detection Outline)

am3zzw00033536

|

am3zzw00033537

|

Repeatability Verification Procedure

-

Note

-

• Match the engine coolant temperature in the recorded freeze frame data/snapshot data, the vehicle speed, and engine speed values to the best extent possible while driving the vehicle.

PID Item/Simulation Item Used In Diagnosis

PID/DATA monitor item table

|

PIDs |

Reference |

|---|---|

|

VLV_TIMING_ACT_IN

|

|

|

VLV_TIMING_DSD_IN

|

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED REPAIR INFORMATION OR SERVICE INFORMATION AVAILABILITY

• Verify related Service Bulletins, on-line repair information, or Service Information availability.

• Is any related Information available?

|

Yes

|

Perform repair or diagnosis according to the available information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snapshot data.

|

—

|

Go to the next step.

|

|

3

|

PURPOSE: INSPECT FOR OTHER RELATED DTCs

• Perform the DTC inspection for the PCM. (See DTC INSPECTION.)

• Are any of the following DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY CONFORMITY OF ACTUAL INTAKE VALVE TIMING

• Start the engine and idle it.

• Access the following PIDs using the M-MDS: (See PID/DATA MONITOR INSPECTION.)

• Perform the following:

• Does the monitor value of the PID item VLV_TIMING_ACT_IN conform to the VLV_TIMING_DSD_IN PID value?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from Step 1.

|

||

|

5

|

PURPOSE: VERIFY CONNECTOR CONNECTIONS

• Start the engine.

• Access the VLV_TIMING_ACT_IN PID using the M-MDS. (See PID/DATA MONITOR INSPECTION.)

• Does the PID value fluctuate when the following connectors are shaken?

|

Yes

|

Repair or replace the applicable wiring harness or connector parts.

Go to Troubleshooting Diagnostic Procedure to perform the repair completion verification.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from Step 1.

|

Troubleshooting Diagnostic Procedure

-

― Perform an inspection of the connectors and wiring harnesses between the battery positive terminal and electric variable valve timing relay and the electric variable valve timing motor/driver.

-

― Perform a unit inspection of the electric variable valve timing relay.

-

― Perform an inspection of the electric variable valve timing drive parts.

-

― Inspect the intake CMP sensor and CKP sensor detection areas for adhesion of foreign matter.

-

― Verify that the primary malfunction is resolved and there are no other malfunctions.

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

2

|

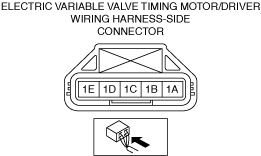

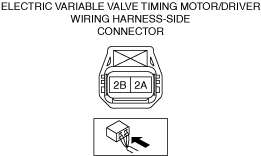

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (See CONNECTOR INSPECTION.)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

3

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

4

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

5

|

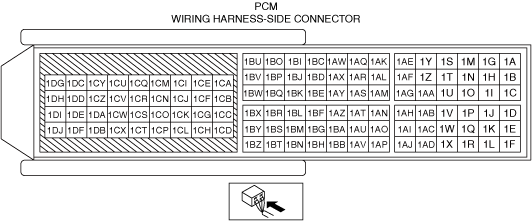

PURPOSE: INSPECT PCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (See CONNECTOR INSPECTION.)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

6

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING RELAY FOR MALFUNCTION

• Inspect the applicable part. (See RELAY INSPECTION.)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

(See RELAY LOCATION [(US)].)

|

||

|

7

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING MOTOR FOR MALFUNCTION

• Inspect the applicable part. (See ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

8

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING ACTUATOR FOR MALFUNCTION

• Inspect the applicable part. (See ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

9

|

PURPOSE: VERIFY ASSEMBLY CONDITION OF TIMING CHAIN

• Verify the condition of the timing chain assembly (intake valve timing, looseness, jumping). (See TIMING CHAIN REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See TIMING CHAIN REMOVAL/INSTALLATION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part.

Assemble the timing chain using the correct timing.

Go to repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

10

|

PURPOSE: VERIFY IF FOREIGN MATTER ON INTAKE CMP SENSOR DETECTION AREA AFFECTS DIAGNOSTIC RESULTS

• Visually inspect for intake CMP sensor. (See CAMSHAFT POSITION (CMP) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See CAMSHAFT POSITION (CMP) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is there foreign matter such as metallic dust on the intake CMP sensor detection area?

|

Yes

|

Remove the foreign matter and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

11

|

PURPOSE: VERIFY IF FOREIGN MATTER ON CKP SENSOR DETECTION AREA AFFECTS DIAGNOSTIC RESULTS

• Visually inspect for CKP sensor. (See CRANKSHAFT POSITION (CKP) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See CRANKSHAFT POSITION (CKP) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is there foreign matter such as metallic dust on the CKP sensor detection area?

|

Yes

|

Remove the foreign matter and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

Repair completion verification 1

|

PURPOSE: VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (See CLEARING DTC.)

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

• Perform the DTC inspection for the PCM. (See DTC INSPECTION.)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step. (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

|

|

No

|

Go to the next step.

|

||

|

Repair completion verification 2

|

PURPOSE: VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection. (See DTC INSPECTION.)

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|