ELECTRIC PARKING BRAKE AUTOMATIC RELEASE FUNCTION DURING ACCELERATION DOES NOT OPERATE [ELECTRIC PARKING BRAKE (US)]

ELECTRIC PARKING BRAKE AUTOMATIC RELEASE FUNCTION DURING ACCELERATION DOES NOT OPERATE [ELECTRIC PARKING BRAKE (US)]

SM2565949

id040328250534

|

Troubleshooting item |

Electric parking brake automatic release function during acceleration does not operate |

|

|---|---|---|

|

Description

|

• Electric parking brake automatic release function during acceleration does not operate.

|

|

|

Possible cause

|

• DSC HU/CM malfunction

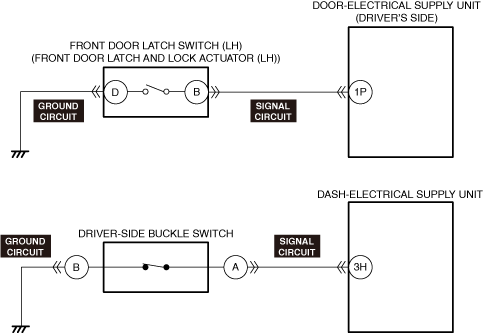

• Front door latch and lock actuator (LH) connector or terminal malfunction

• Front door latch switch (LH) malfunction

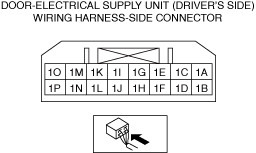

• Door-electrical supply unit, driver connector or terminal malfunction

• Short to ground in front door latch switch (LH) signal circuit

• Door-electrical supply unit, driver malfunction

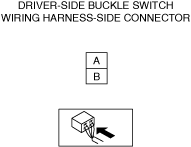

• Driver-side buckle switch connector or terminal malfunction

• Driver-side buckle switch malfunction

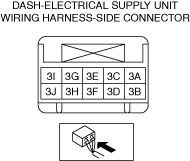

• Dash-electrical supply unit connector or terminal malfunction

• Short to ground in driver-side buckle switch signal circuit

• Dash-electrical supply unit malfunction

|

|

|

||

|

|

|

|

|

|

Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

VERIFY ALL SYSTEM DTCs

• Switch the ignition off.

• Switch the ignition ON (engine off or on) and wait for 10 s or more.

• Perform a DTC inspection using the M-MDS. (See DTC INSPECTION.)

• Are any DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

(See DTC TABLE [DSC HU/CM (US)].)

|

|

No

|

Go to the next step.

|

||

|

2

|

VERIFY IF THE ELECTRIC PARKING BRAKE WARNING LIGHT IS TURNED ON

• Verify if the electric parking brake warning light is turned on.

• Is the electric parking brake warning light turned on?

|

Yes

|

Perform an inspection referring to “ELECTRIC PARKING BRAKE WARNING LIGHT TURNS ON”.

|

|

No

|

Go to the next step.

|

||

|

3

|

DETERMINE MALFUNCTIONING LOCATION BY PERFORMING PID/DATA MONITOR INSPECTION

• Using the M-MDS, display the following PIDs for the door-electrical supply unit, driver. (See PID/DATA MONITOR INSPECTION.)

• Using the M-MDS, display the following PIDs for the dash-electrical supply unit. (See PID/DATA MONITOR INSPECTION.)

• Does the PID monitoring value switch correctly in conjunction with the opening/closing of the front door (LH) or with the driver’s seat belt fastened?

|

Yes

|

Replace the DSC HU/CM, and perform the repair completion verification.

|

|

No

|

Not in conjunction with front door (LH) open/close

• Go to the next step.

Not in conjunction with driver’s seat belt fastened

• Go to Step 8.

|

||

|

4

|

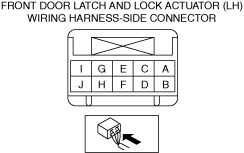

INSPECT FRONT DOOR LATCH AND LOCK ACTUATOR (LH) CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Disconnect the front door latch and lock actuator (LH) connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, and perform the repair completion verification.

|

||

|

5

|

INSPECT FRONT DOOR LATCH SWITCH (LH)

• Inspect the front door latch switch (LH). (See FRONT DOOR LATCH AND LOCK ACTUATOR INSPECTION [(US)].)

• Is the front door latch switch (LH) normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the front door latch and lock actuator (LH), and perform the repair completion verification.

|

||

|

6

|

INSPECT DOOR-ELECTRICAL SUPPLY UNIT,DRIVER CONNECTOR CONDITION

• Disconnect the door-electrical supply unit, driver connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, and perform the repair completion verification.

|

||

|

7

|

INSPECT FRONT DOOR LATCH SWITCH (LH) SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the signal circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Replace the door-electrical supply unit, and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location.

|

||

|

8

|

INSPECT DRIVER-SIDE BUCKLE SWITCH CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Disconnect the driver-side buckle switch connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, and perform the repair completion verification.

|

||

|

9

|

INSPECT DRIVER-SIDE BUCKLE SWITCH

• Inspect the driver-side buckle switch. (See BUCKLE SWITCH INSPECTION [(US)].)

• Is the driver-side buckle switch normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the driver-side front buckle, and perform the repair completion verification.

|

||

|

10

|

INSPECT DASH-ELECTRICAL SUPPLY UNIT CONNECTOR CONDITION

• Disconnect the dash-electrical supply unit connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, and perform the repair completion verification.

|

||

|

11

|

INSPECT DRIVER-SIDE BUCKLE SWITCH SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the signal circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Replace the dash-electrical supply unit, and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location, and perform the repair completion verification.

|

||

|

Repair completion verification

|

VERIFY THAT MALFUNCTION SYMPTOMS DO NOT RECUR AFTER REPAIR

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting.

Explain to the customer what has been repaired.

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

|