EXHAUST SMOKE [SKYACTIV-G]

EXHAUST SMOKE [SKYACTIV-G]

SM2334620

id0103s4890600

|

Troubleshooting item |

Exhaust smoke |

|

|---|---|---|

|

Description

|

• Blue, black, or white smoke from exhaust system.

|

|

|

Possible cause

|

Blue smoke (Burning oil):

• PCV valve malfunction

• Engine internal oil leakage

White smoke (Water in combustion):

• Cooling system malfunction (coolant loss)

• Engine internal coolant leakage

Black smoke (Rich fuel mixture):

• Erratic signal to PCM

• Improper fuel injection timing and amount

• Air cleaner restriction

• Intake-air system is collapsed or restricted

• Leakage at engine intake manifold and/or exhaust manifold

• Inadequate/Excessive fuel pressure

• Ignition system malfunction

• Improper engine compression

• Improper intake valve timing

• Improper exhaust valve timing

• Injector driver (built-into PCM) malfunction

|

|

|

Possible cause

|

|

|

|

||

|

||

|

||

-

Caution

-

• Verify the malfunction symptom according to not only the PID value but also the symptom troubleshooting.

Related PIDs

|

PIDs |

Reference |

|---|---|

|

APP1

|

|

|

APP2

|

|

|

ECT

|

|

|

ECT_VOLT

|

|

|

ECT2

|

|

|

ECT2_VOLT

|

|

|

FUEL_PRES

|

|

|

IAT

|

|

|

LOAD_CALC

|

|

|

LONG_FUEL_TRIM

|

|

|

MAF

|

|

|

MAP

|

|

|

MAP_VOLT

|

|

|

A/F_SEN_CUR

|

|

|

HO2S_OUT_VOLT

|

|

|

ENG_RPM

|

|

|

SHRT_FUEL_TRIM

|

|

|

TP_RELAT

|

|

|

VSS

|

Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

VERIFY EXHAUST COLOR

• What color is smoke coming from the exhaust system?

|

Blue

|

Burning oil is indicated.

• Go to the next step.

|

|

White

|

Water in combustion is indicated.

• Go to Step 4.

|

||

|

Black

|

Rich fuel mixture is indicated.

• Go to Step 5.

|

||

|

2

|

INSPECT PCV VALVE FOR MALFUNCTION

• Inspect the applicable part. (See POSITIVE CRANKCASE VENTILATION (PCV) VALVE INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See POSITIVE CRANKCASE VENTILATION (PCV) VALVE INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

3

|

INSPECT ENGINE INTERNAL PARTS

• Inspect for the following engine internal parts:

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Engine internal parts are normal.

• If other driveability symptoms are present:

|

||

|

4

|

INSPECT ENGINE FOR ENGINE COOLANT LEAKAGE

• Does the cooling system hold the coolant pressure? (See ENGINE COOLANT LEAKAGE INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See ENGINE COOLANT LEAKAGE INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

|

Yes

|

Inspect the following:

• Cylinder head gasket leakage

• Intake manifold gasket leakage

• Cracked or porous engine block

If there is any malfunction:

• Repair or replace the malfunctioning location and perform the repair completion verification.

If there is no malfunction:

• If other driveability symptoms are present:

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

5

|

VERIFY CURRENT INPUT SIGNAL STATUS

• Access the following PIDs using the M-MDS: (See PID/DATA MONITOR INSPECTION.)

• Monitor the PIDs under the black smoke appeared engine condition.

• Do the PIDs indicate normal according to engine conditions? (See PID/DATA MONITOR TABLE [PCM (SKYACTIV-G (US))].)

|

Yes

|

Go to the next step.

|

|

No

|

APP1, APP2 PIDs are not as specified:

• Inspect the APP sensor No.1 and No.2. (See ACCELERATOR PEDAL POSITION (APP) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See ACCELERATOR PEDAL POSITION (APP) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

ECT, ECT_VOLT, ECT2, ECT2_VOLT PIDs are not as specified:

• Inspect the ECT sensor No.1 and No.2. (See ENGINE COOLANT TEMPERATURE (ECT) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See ENGINE COOLANT TEMPERATURE (ECT) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

IAT PID is not as specified:

• Inspect the IAT sensor No.1. (See INTAKE AIR TEMPERATURE (IAT) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See INTAKE AIR TEMPERATURE (IAT) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

MAF PID is not as specified:

|

||

|

5

|

—

|

No

|

MAP, MAP_VOLT PIDs are not as specified:

• Inspect the MAP sensor. (See MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

TP_RELAT PID is not as specified:

• Inspect the TP sensor. (See THROTTLE POSITION (TP) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See THROTTLE POSITION (TP) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

A/F_SEN_CUR, SHRT_FUEL_TRIM, LONG_FUEL_TRIM PIDs are not as specified:

• Inspect the A/F sensor. (See AIR FUEL RATIO (A/F) SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See AIR FUEL RATIO (A/F) SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

HO2S_OUT_VOLT PID is not as specified:

• Inspect the HO2S. (See HEATED OXYGEN SENSOR (HO2S) INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See HEATED OXYGEN SENSOR (HO2S) INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

Repair or replace the malfunctioning location.

• If the malfunction remains:

|

|

6

|

INSPECT FUEL INJECTOR OPERATION

• Perform the Fuel Injector Operation Inspection. (See FUEL INJECTOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See FUEL INJECTOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Do the fuel injectors operate properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

7

|

INSPECT INTAKE AIR SYSTEM

• Inspect the following for intake-air system:

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

8

|

INSPECT EXHAUST SYSTEM FOR LEAKAGE

• Visually inspect for exhaust gas leakage from exhaust manifold.

• Is there any leakage?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

9

|

INSPECT FUEL PRESSURE (HIGH-SIDE)

• Start the engine and warm it up completely.

• Access the FUEL_PRES PID using the M-MDS at idle. (See PID/DATA MONITOR INSPECTION.)

• Is the FUEL_PRES PID value within specification?

Specification:

• Approx. 3 MPa {31 kgf/cm2, 435 psi} (Thailand specs.)

• Approx. 10 MPa {102 kgf/cm2, 1450 psi} (except Thailand specs.)

|

Yes

|

Go to Step 13.

|

|

No

|

Lower than specification:

• Inspect the following:

• If there is any malfunction:

• If there is no malfunction:

Higher than specification:

• Go to the next step.

|

||

|

10

|

DETERMINE IF MALFUNCTION CAUSE IS FUEL PRESSURE SENSOR OR HIGH PRESSURE FUEL PUMP

• Is the vehicle acceleration performance normal?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 12.

|

||

|

11

|

INSPECT FUEL PRESSURE SENSOR FOR MALFUNCTION

• Inspect the applicable part. (See FUEL PRESSURE SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See FUEL PRESSURE SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to Step 13.

|

|

No

|

Replace the fuel distributor and perform the repair completion verification.

|

||

|

12

|

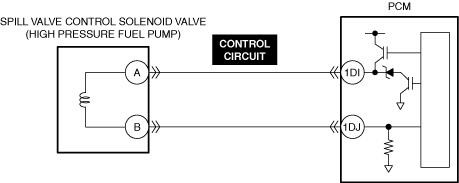

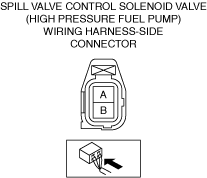

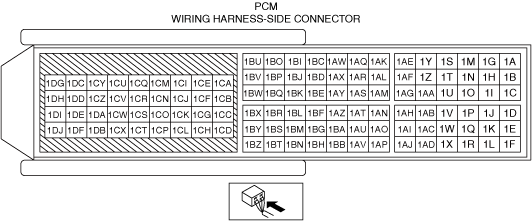

INSPECT SPILL VALVE CONTROL SOLENOID VALVE CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Replace the high pressure fuel pump and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

13

|

INSPECT FUEL PRESSURE (LOW-SIDE)

• Connect the fuel pressure gauge between fuel pump and high pressure fuel pump.

• Measure the low side fuel pressure. (See FUEL LINE PRESSURE INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See FUEL LINE PRESSURE INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the low side fuel pressure within specification?

Specification:

• 475—555 kPa {4.85—5.65 kgf/cm2, 68.9—80.4 psi}

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the following:

• Fuel line restriction

• Fuel filter clogged

|

||

|

14

|

INSPECT IGNITION SYSTEM OPERATION

• Perform the Spark Test. (See SPARK INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See SPARK INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is a strong blue spark visible at each cylinder?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

15

|

INSPECT ENGINE COMPRESSION

• Measure the compression pressure for each cylinder. (See COMPRESSION INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See COMPRESSION INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Are compression pressures within specification?

|

Yes

|

Injector driver malfunction.

• Replace the PCM. (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

If the problem remains, overhaul the engine and perform the repair completion verification.

|

|

No

|

Inspect the following:

• Damaged valve seat

• Worn valve stem and valve guide

• Worn or stuck piston ring

• Worn piston, piston ring or cylinder

• Improper intake valve timing

• Improper exhaust valve timing

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

|

||

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM. (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

|

|

No

|

Replace the PCM.

|