TROUBLESHOOTING PROCEDURE [(US)]

TROUBLESHOOTING PROCEDURE [(US)]

SM2337314

id9902000002a1

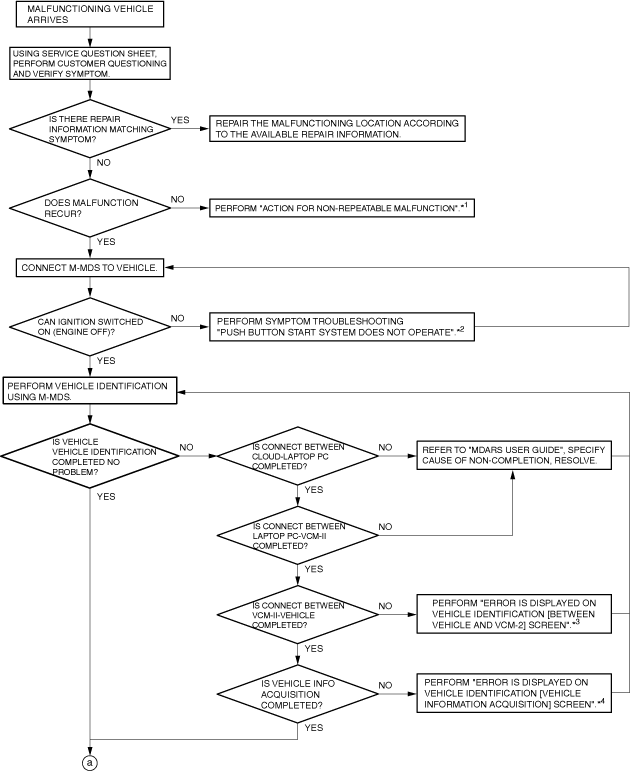

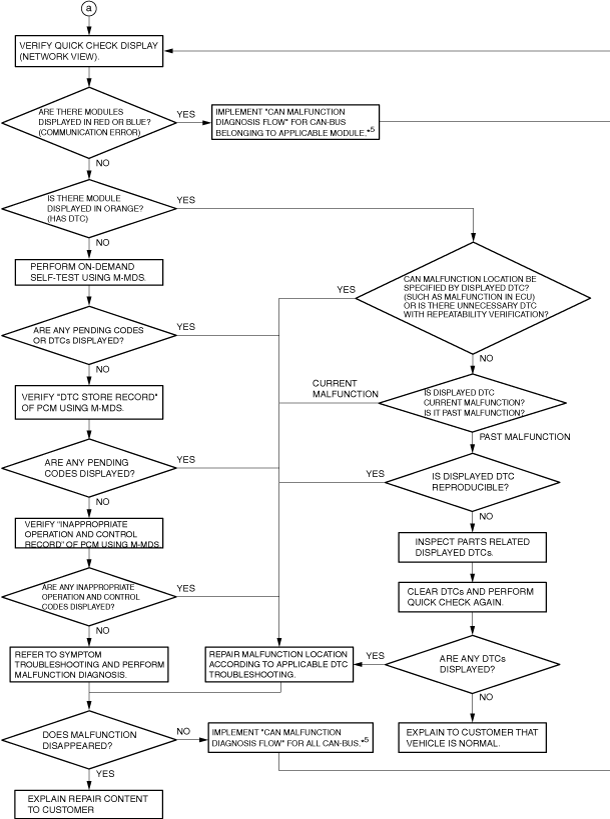

Troubleshooting Procedure

am3zzw00031577

|

am3zzw00024768

|

Action for Non-repeatable Malfunction

-

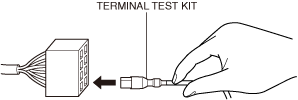

1. Perform the DTC inspection and repair the malfunctioning location according to the applicable DTC troubleshooting. (See DTC INSPECTION.)2. Based on the repair order form, attempt to drive the vehicle or perform tests to determine the malfunction cause according to the data (such as module voltage) at that time.3. Perform vibration inspection. (See Vibration inspection.)4. Inspect the female terminals on the connector of the electric component which is suspected to be the cause of the malfunction for poor connection. (See ELECTRICAL SYSTEM [(US)].)

-

Note

-

• Tool used (Reference): terminal test kit (49US-15-KIT)

am3zzw00027046

am3zzw00027046

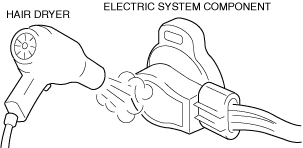

5. Verify if the malfunction symptom occurs during high engine load (switches such as headlights, A/C, wipers are on).6. If a commercially-available electrical device has been installed, verify if the malfunction symptom occurs while the device is removed.7. Warm the electric system components using a hair dryer and verify that the voltage (resistance) does not change. atsvuw000000918. Perform water spraying inspection. (See Water spraying inspection.)

atsvuw000000918. Perform water spraying inspection. (See Water spraying inspection.) -

Vibration inspection

-

• If there is a malfunction while the vehicle vibrates such as while driving on a rough-road, perform the following procedure.

-

Note

-

• The following are possible causes for an electrical malfunction caused by vehicle vibration.

-

― Connector connection malfunction― There is no play in the wiring harness.― The wiring harness contacts a moving part.― The wiring harness is close to a high-temperature part.

• If the wiring harness is not routed correctly, it may be caught between some parts.• The main areas to be inspected include the connecting area of a connector, areas that vibrate, or areas where a wiring harness passes though the firewall or body panel. -

-

1.Display the PIDs for the electrical system components (such as switches, sensors, actuators, and relays) suspected to be the malfunction cause. (See PID/DATA MONITOR INSPECTION.)

2.When inspecting a switch, turn the switch on manually.

-

Caution

-

• Do not apply excessive force when shaking the part or wiring harness. Otherwise, an open circuit may occur.

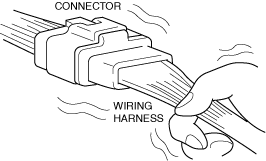

3.Lightly shake connectors and wiring harnesses while verifying the PID value.

atsvuw00000070

|

-

• If a PID value does not stabilize, inspect the connector and terminal for poor connection.

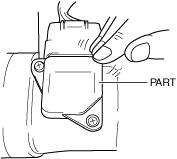

4.Lightly shake a part while verifying the PID value.

atsvuw00000071

|

-

• If the PID value does not stabilize or a part mis-operation occurs, inspect the connector and terminal for a poor connection and the part for poor installation.

5.Operate the simulation function for the electric system component suspected to be the malfunction cause. (See SIMULATION INSPECTION.)

6.Lightly shake the part after operating the simulation function.

-

• If abnormal noise occurs from the part, inspect the connector and terminal for poor connection and the part for poor installation.

Water spraying inspection

-

• If the malfunction occurred during high humidity, heavy rain, or heavy snow conditions, perform the following procedure.

-

Caution

-

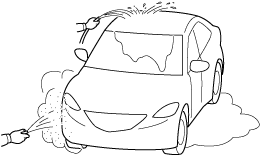

• Spray water on the front of the radiator to change the temperature and humidity indirectly. If water leaks into the vehicle, it could damage a module. If there is the possibility of water leaking into the vehicle, carefully perform the inspection.

1.Display the PIDs for the electrical system components (such as switches, sensors, actuators, and relays) suspected to be the malfunction cause. (See PID/DATA MONITOR INSPECTION.)

2.When inspecting a switch, turn the switch on manually.

3.Spray water on the vehicle.

azzjjw00001888

|

-

• If the PID value does not stabilize or there is a malfunction, inspect the applicable part.