DTC P2B61:00 [PCM (SKYACTIV-G (US))]

DTC P2B61:00 [PCM (SKYACTIV-G (US))]

SM2565530

id0102t41680u0

-

Note

-

• To determine the malfunctioning part, proceed with the diagnostics from “Function Inspection Using M-MDS”.

Details On DTCs

|

Description |

Coolant control valve circuit range/performance |

||

|---|---|---|---|

|

Detection condition

|

Determination conditions

|

• The coolant control valve control duty value is 89% or more for a continuous 2 s.

|

|

|

Preconditions

|

• Not applicable

|

||

|

Drive cycle

|

• 1

|

||

|

Self test type

|

• CMDTC self test

|

||

|

Sensor used

|

• Coolant control valve position sensor

|

||

|

Fail-safe function

|

• PCM restricts engine torque.

|

||

|

Vehicle status when DTCs are output

|

• Not applicable

|

||

|

Possible cause

|

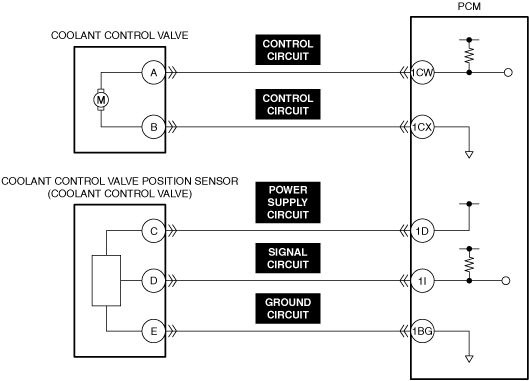

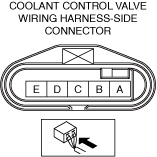

• Coolant control valve connector or terminals malfunction

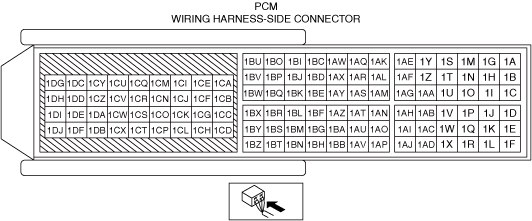

• PCM connector or terminals malfunction

• Coolant control valve sticking, or foreign matter penetration

• Short to ground in coolant control valve control circuit

• Short to ground in any of the following coolant control valve position sensor circuits.

• Short circuit in coolant control valve control circuits

• Short circuit between any of the following coolant control valve position sensor circuits.

• Open circuit in coolant control valve control circuit

• Open circuit in any of the following coolant control valve position sensor circuits.

• Coolant control valve malfunction

• Coolant control valve position sensor malfunction

• PCM malfunction

|

||

|

|||

|

|||

|

|||

Function Explanation (DTC Detection Outline)

Repeatability Verification Procedure

1.Warm up the engine to allow the engine coolant temperature to reach 50—95 °C {122—203 °F}.

-

Note

-

• The difference between PIDs ENG_COOL_VLV_POS_ACT and ENG_COOL_VLV_POS_COMD displayed the engine coolant control valve opening angle must be within 2 °.• Match the engine coolant temperature in the recorded freeze frame data/snapshot data, the vehicle speed, and engine speed values to the best extent possible while driving the vehicle.

2.Try to reproduce the malfunction by driving the vehicle for 5 min based on the values in the freeze frame data/snapshot data.

PID Item/Simulation Item Used In Diagnosis

PID/DATA monitor item table

|

PIDs |

Reference |

|---|---|

|

ENG_COOL_VLV_POS_COMD

|

|

|

ENG_COOL_VLV_POS_ACT

|

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: IDENTIFY TRIGGER DTC FOR FREEZE FRAME DATA

• Is the DTC P2B61:00 on freeze frame data?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the troubleshooting procedure for DTC on freeze frame data.

|

||

|

2

|

PURPOSE: VERIFY RELATED REPAIR INFORMATION OR SERVICE INFORMATION AVAILABILITY

• Verify related Service Bulletins, on-line repair information, or Service Information availability.

• Is any related Information available?

|

Yes

|

Perform repair or diagnosis according to the available information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snapshot data.

|

—

|

Go to the next step.

|

|

4

|

PURPOSE: INSPECT FOR OTHER RELATED DTCs

• Perform the DTC inspection for the PCM. (See DTC INSPECTION.)

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: VERIFY COOLANT CONTROL VALVE POSITION SENSOR INPUT SIGNAL

• Start the engine and idle it.

• Access the ENG_COOL_VLV_POS_ACT PID using the M-MDS. (See PID/DATA MONITOR INSPECTION.)

• Is the PID value within specification?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from Step 1.

|

||

|

6

|

PURPOSE: VERIFY CONNECTOR CONNECTIONS

• Start the engine.

• Access the ENG_COOL_VLV_POS_ACT PID using the M-MDS. (See PID/DATA MONITOR INSPECTION.)

• Does the PID value fluctuate when the following connectors are shaken?

|

Yes

|

Inspect the related wiring harness and connector.

• Repair or replace the malfunctioning part.

Go to Troubleshooting Diagnostic Procedure to perform the repair completion verification.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from Step 1.

|

Troubleshooting Diagnostic Procedure

-

― Perform an inspection of the connectors and wiring harnesses between the coolant control valve and the PCM.

-

― Perform a unit inspection of the coolant control valve.

-

― Perform a unit inspection of the coolant control valve position sensor.

-

― Verify that the primary malfunction is resolved and there are no other malfunctions.

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY IF COOLANT CONTROL VALVE IS INSTALLED CORRECTLY

• Verify the coolant control valve installation condition. (See COOLANT CONTROL VALVE REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See COOLANT CONTROL VALVE REMOVAL/INSTALLATION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the installation condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Correctly install the coolant control valve and perform the repair completion verification.

|

||

|

2

|

PURPOSE: INSPECT COOLANT CONTROL VALVE CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

3

|

PURPOSE: INSPECT COOLANT CONTROL VALVE POSITION SENSOR POWER SUPPLY CIRCUITS, SIGNAL CIRCUITS, AND GROUND CIRCUITS FOR SHORT TO GROUND

• Inspect the applicable circuit for open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

4

|

PURPOSE: INSPECT COOLANT CONTROL VALVE CONTROL CIRCUITS FOR SHORT CIRCUIT

• Inspect the applicable circuits for a short circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

5

|

PURPOSE: INSPECT COOLANT CONTROL VALVE POSITION SENSOR POWER SUPPLY CIRCUITS, SIGNAL CIRCUITS, AND GROUND CIRCUITS FOR SHORT CIRCUIT

• Inspect the applicable circuits for a short circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

6

|

PURPOSE: INSPECT COOLANT CONTROL VALVE CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

7

|

PURPOSE: INSPECT COOLANT CONTROL VALVE POSITION SENSOR POWER SUPPLY CIRCUITS, SIGNAL CIRCUITS, AND GROUND CIRCUITS FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

8

|

PURPOSE: INSPECT COOLANT CONTROL VALVE FOR MALFUNCTION

• Inspect the applicable part. (See COOLANT CONTROL VALVE INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See COOLANT CONTROL VALVE INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

9

|

PURPOSE: INSPECT COOLANT CONTROL VALVE POSITION SENSOR FOR MALFUNCTION

• Inspect the applicable part. (See COOLANT CONTROL VALVE POSITION SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See COOLANT CONTROL VALVE POSITION SENSOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

Repair completion verification 1

|

PURPOSE: VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (See CLEARING DTC.)

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

• Perform the DTC inspection for the PCM. (See DTC INSPECTION.)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step. (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].) (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].)

|

|

No

|

Go to the next step.

|

||

|

Repair completion verification 2

|

PURPOSE: VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection. (See DTC INSPECTION.)

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|