AIR BAG SYSTEM WARNING LIGHT ILLUMINATES CONSTANTLY [AIR BAG SYSTEM]

AIR BAG SYSTEM WARNING LIGHT ILLUMINATES CONSTANTLY [AIR BAG SYSTEM]

SM2335882

id0803a3814400

|

Troubleshooting item |

Air bag system warning light illuminates constantly |

|

|---|---|---|

|

Description

|

• After switching the ignition ON (engine off or on), the air bag system warning light turns on and remains on after approx. 6 s have elapsed.

|

|

|

Possible cause

|

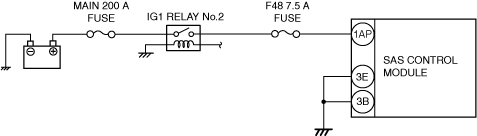

• IG1 relay No.2 malfunction

• DTCs are stored in the SAS control module.

• Battery malfunction

• Generator system malfunction

• SAS control module connector or terminal malfunction

• SAS control module malfunction

• Instrument cluster malfunction

• Malfunction in CAN line between the SAS control module and instrument cluster

• Open circuit in SAS control module power supply circuit

• Short to ground in SAS control module power supply circuit

• Open circuit in SAS control module ground circuit

|

|

|

||

|

||

-

Warning

-

• Handling the component parts improperly can accidentally operate (deploy) the air bag module, which may seriously injure you. Read the service warnings/cautions and the workshop manual before handling the air bag system components. (See AIR BAG SYSTEM SERVICE WARNINGS [STANDARD DEPLOYMENT CONTROL SYSTEM – MEXICO SPEC.].) (See AIR BAG SYSTEM SERVICE CAUTIONS [STANDARD DEPLOYMENT CONTROL SYSTEM – MEXICO SPEC.].) (See AIR BAG SYSTEM SERVICE WARNINGS [TWO-STEP DEPLOYMENT CONTROL SYSTEM – US/CANADA SPEC.].) (See AIR BAG SYSTEM SERVICE CAUTIONS [TWO-STEP DEPLOYMENT CONTROL SYSTEM – US/CANADA SPEC.].)

Diagnostic Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

INSPECT IG1 RELAY No.2

• Switch the ignition off.

• Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Inspect the IG1 relay No.2. (See RELAY INSPECTION.)

• Is the IG1 relay No.2 normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the IG1 relay No.2, then perform the repair completion verification.

(See RELAY LOCATION [(US)].)

|

||

|

2

|

INSPECT SAS CONTROL MODULE DTC

• Perform the SAS control module DTC inspection using the M-MDS. (See DTC INSPECTION.)

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECT BATTERY

• Inspect the battery. (See BATTERY INSPECTION [(US)].)

• Is the battery normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace or charge the battery.

(See BATTERY RECHARGING [(US)].)

Then perform the repair completion verification.

|

||

|

4

|

INSPECT GENERATOR

• Inspect the generator. (See GENERATOR INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))].) (See GENERATOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].)

• Is the generator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the generator, then go to perform the repair completion verification.

|

||

|

5

|

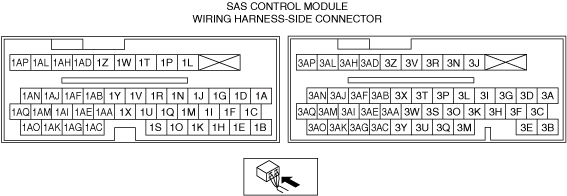

VERIFY THAT SAS CONTROL MODULE CONNECTOR IS CONNECTED

• Switch the ignition off.

• Disconnect the negative battery terminal and wait for 1 min or more. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Verify the condition of the SAS control module connectors. (See SAS CONTROL MODULE REMOVAL/INSTALLATION [STANDARD DEPLOYMENT CONTROL SYSTEM – MEXICO SPEC.].) (See SAS CONTROL MODULE REMOVAL/INSTALLATION [TWO-STEP DEPLOYMENT CONTROL SYSTEM – US/CANADA SPEC.].)

• Are all SAS control module connectors securely connected?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the connector properly, then go to perform the repair completion verification.

|

||

|

6

|

VERIFY THAT INSTRUMENT CLUSTER CONNECTOR IS CONNECTED

• Remove the instrument cluster. (See INSTRUMENT CLUSTER REMOVAL/INSTALLATION.)

• Are all instrument cluster connectors securely connected?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the connector properly, then go to perform the repair completion verification.

|

||

|

7

|

INSPECT DTCs IN SAS CONTROL MODULE

• Connect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Switch the ignition ON (engine off or on).

• Clear the DTC for the SAS control module using the M-MDS. (See CLEARING DTC.)

• Inspect the DTC for the SAS control module on-board diagnostic system. (See DTC INSPECTION.)

• Have DTCs been recorded in memory?

|

Yes

|

Perform the applicable DTC inspection, then perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

8

|

INSPECT DTCs IN BCM

• Inspect the DTC for the BCM on-board diagnostic system. (See DTC INSPECTION.)

• Are the any DTCs present?

|

Yes

|

Perform the applicable DTC inspection, then perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

9

|

VERIFY SAS CONTROL MODULE CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery terminal and wait for 1 min or more. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Disconnect all SAS control module connectors. (See SAS CONTROL MODULE REMOVAL/INSTALLATION [STANDARD DEPLOYMENT CONTROL SYSTEM – MEXICO SPEC.].) (See SAS CONTROL MODULE REMOVAL/INSTALLATION [TWO-STEP DEPLOYMENT CONTROL SYSTEM – US/CANADA SPEC.].)

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the air bag harness, then perform the repair completion verification.

|

||

|

10

|

INSPECT SAS CONTROL MODULE POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

11

|

INSPECT SAS CONTROL MODULE GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the ground circuit for an open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Repair the instrument cluster, then perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

Repair completion verification

|

VERIFY THAT MALFUNCTION SYMPTOMS DO NOT RECUR AFTER REPAIR

• Connect the SAS control module connectors.

• Reconnect all disconnected connectors.

• Connect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(US)].)

• Switch the ignition ON (engine off or on).

• Does the air bag system warning light illuminate for approx. 6 s and turn off?

|

Yes

|

Verify that there are no DTCs in the memory. If there are no DTCs, the troubleshooting is completed.

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, replace the SAS control module. (See SAS CONTROL MODULE REMOVAL/INSTALLATION [STANDARD DEPLOYMENT CONTROL SYSTEM – MEXICO SPEC.].) (See SAS CONTROL MODULE REMOVAL/INSTALLATION [TWO-STEP DEPLOYMENT CONTROL SYSTEM – US/CANADA SPEC.].)

|

||