TRUNK/LIFTGATE DOES NOT OPEN [SECURITY AND LOCKS]

TRUNK/LIFTGATE DOES NOT OPEN [SECURITY AND LOCKS]

SM2336283

id0903k7023000

Outline

|

Description

|

• Trunk/liftgate does not open even if trunk lid opener switch/liftgate opener switch is pressed

|

|

|

Possible cause

|

• Connector or terminal malfunction of the following parts:

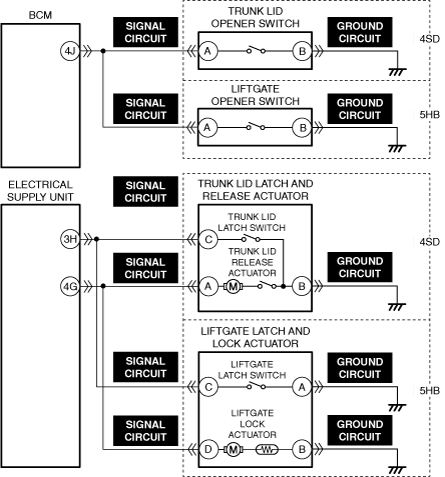

• Open circuit in trunk lid opener switch signal circuit (4SD)/liftgate opener switch signal circuit (5HB)

• Open circuit in trunk lid opener switch ground circuit (4SD)/liftgate opener switch ground circuit (5HB)

• Short to ground or open circuit in trunk lid latch and release actuator signal circuit (4SD)/liftgate latch and lock actuator signal circuit (5HB)

• Open circuit in trunk lid latch and release actuator ground circuit (4SD)/liftgate latch and lock actuator ground circuit (5HB)

• Trunk lid opener switch (4SD)/liftgate opener switch (5HB) malfunction

• Trunk lid latch and release actuator (4SD)/liftgate latch and lock actuator (5HB) malfunction

• Electrical supply unit malfunction

• BCM malfunction

|

|

|

||

|

|

|

|

|

|

|

||

Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

VERIFY ALL SYSTEM DTCs

• Perform the DTC inspection. (See DTC INSPECTION.)

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

2

|

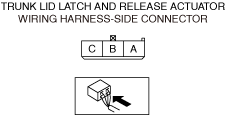

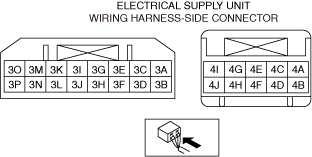

INSPECT TRUNK LID OPENER SWITCH (4SD)/LIFTGATE OPENER SWITCH (5HB), TRUNK LID LATCH AND RELEASE ACTUATOR (4SD)/LIFTGATE LATCH AND LOCK ACTUATOR (5HB), BCM, AND ELECTRICAL SUPPLY UNIT CONNECTORS FOR MALFUNCTION

• Inspect the applicable connector and terminal. (See CONNECTOR INSPECTION.)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

3

|

INSPECT TRUNK LID OPENER SWITCH SIGNAL CIRCUIT (4SD)/LIFTGATE OPENER SWITCH SIGNAL CIRCUIT (5HB) FOR OPEN CIRCUIT

• Inspect the signal circuit for open circuit (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

4

|

INSPECT TRUNK LID OPENER SWITCH GROUND CIRCUIT (4SD)/LIFTGATE OPENER SWITCH GROUND CIRCUIT (5HB) FOR OPEN CIRCUIT

• Inspect the ground circuit for open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

5

|

INSPECT TRUNK LID LATCH AND RELEASE ACTUATOR SIGNAL CIRCUIT (4SD)/LIFTGATE LATCH AND LOCK ACTUATOR SIGNAL CIRCUIT (5HB) FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the signal circuit for a short to ground and open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

6

|

INSPECT TRUNK LID LATCH AND RELEASE ACTUATOR GROUND CIRCUIT (4SD)/LIFTGATE LATCH AND LOCK ACTUATOR GROUND CIRCUIT (5HB) FOR OPEN CIRCUIT

• Inspect the ground circuit for open circuit. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

7

|

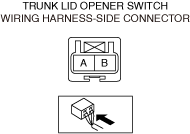

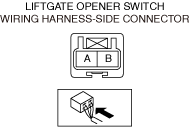

INSPECT TRUNK LID OPENER SWITCH (4SD)/LIFTGATE OPENER SWITCH (5HB) FOR MALFUNCTION

• Inspect the applicable part. (See TRUNK LID OPENER SWITCH INSPECTION.) (See LIFTGATE OPENER SWITCH INSPECTION.)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

8

|

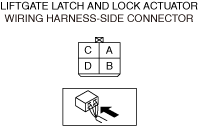

INSPECT TRUNK LID LATCH AND RELEASE ACTUATOR (4SD)/LIFTGATE LATCH AND LOCK ACTUATOR (5HB) FOR MALFUNCTION

• Inspect the applicable part. (See TRUNK LID LATCH AND RELEASE ACTUATOR INSPECTION.) (See LIFTGATE LATCH AND LOCK ACTUATOR INSPECTION.)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

9

|

INSPECT ELECTRICAL SUPPLY UNIT FOR MALFUNCTION

• Inspect the applicable part. (See ELECTRICAL SUPPLY UNIT (ESU) INSPECTION.)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

Repair completion verification

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction is not resolved, replace the BCM. (See BODY CONTROL MODULE (BCM) REMOVAL/INSTALLATION.)

|