NO.2 ANY OF THE FOLLOWING LIGHTS STAY ON: (ABS WARNING LIGHT, TCS/DSC INDICATOR LIGHT AND/OR DSC OFF INDICATOR LIGHT) [DYNAMIC STABILITY CONTROL (DSC)]

NO.2 ANY OF THE FOLLOWING LIGHTS STAY ON: (ABS WARNING LIGHT, TCS/DSC INDICATOR LIGHT AND/OR DSC OFF INDICATOR LIGHT) [DYNAMIC STABILITY CONTROL (DSC)]

SM2335151

id0403b2890500

|

Troubleshooting item |

Any of the following lights stay on: (ABS warning light, TCS/DSC indicator light and/or DSC OFF indicator light) |

|---|---|

|

Possible cause

|

• No connection at DSC HU/CM connector (When DSC HU/CM connector comes off, ABS warning light, brake system warning light, TCS/DSC indicator light, and DSC OFF indicator light illuminate.)

• DSC HU/CM detected malfunction. (Input and output device malfunction)

• DSC HU/CM detects low voltage in power supply.

• DSC HU/CM ground malfunction (When DSC HU/CM ground is not securely connected, ABS warning light, brake system warning light, TCS/DSC indicator light, and DSC OFF indicator light illuminate but diagnostic trouble code does not display.)

• DSC HU/CM does not operate.

• PCM detected malfunction.

• Body control module (BCM) detected malfunction.

• Error signal input from PCM

• Communication error between DSC HU/CM and instrument cluster

• Communication error between DSC HU/CM and PCM

• Communication error between DSC HU/CM and EPS control module

• Communication error between DSC HU/CM and body control module (BCM)

• Communication error between DSC HU/CM and TCM (ATX)

• Communication error between DSC HU/CM and SAS control module

• After replacing SAS control module low-G sensor and yaw rate sensor initialization have not been performed.

• After replacing DSC HU/CM brake fluid pressure sensor initialization has not been performed.

• Non-completion of module configuration (When module configuration does not carried out, after replacing DSC HU/CM, ABS warning light will stay on.)

• DSC HU/CM internal malfunction

|

|

|

|

|

Diagnostic procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

CONFIRM DSC HU/CM DTC

• Retrieve the DSC HU/CM DTC using the M-MDS. (See DTC INSPECTION.)

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

(See DTC TABLE [DSC HU/CM (US)].)

|

|

No

|

If communication error message is displayed on the M-MDS screen:

• Go to the next step.

If communication error message is not displayed:

• Go to Step 5.

|

||

|

2

|

INSPECT CONNECTION OF DSC HU/CM CONNECTOR

• Inspect for connection of the DSC HU/CM connector.

• Is the DSC HU/CM connector connected securely?

|

Yes

|

Go to the next step.

|

|

No

|

Connect the DSC HU/CM connector securely, then go to Step 5.

|

||

|

*3

|

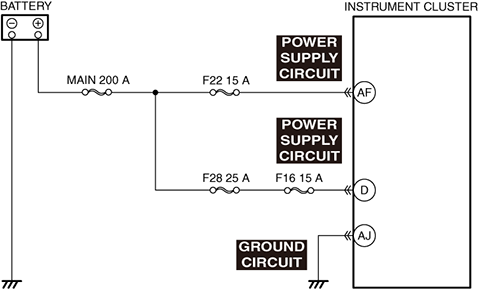

INSPECT DSC HU/CM POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location, and perform the repair completion verification.

|

||

|

*4

|

INSPECT DSC HU/CM GROUND CIRCUIT FOR SHORT TO POWER SUPPLY AND OPEN CIRCUIT

• Inspect the ground circuit for an open circuit and short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Replace the DSC HU/CM, and perform the repair completion verification. (open circuit in the DSC HU/CM)

|

|

No

|

Repair or replace the malfunctioning location, and perform the repair completion verification.

|

||

|

5

|

CONFIRM PCM DTCs

• Retrieve the PCM DTCs using the M-MDS. (See DTC INSPECTION.)

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

||

|

6

|

CONFIRM BODY CONTROL MODULE (BCM) DTC

• Retrieve the body control module (BCM) DTC using the M-MDS. (See DTC INSPECTION.)

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

||

|

7

|

VERIFY IF MALFUNCTION CAUSED BY INITIALIZATION PROCEDURE FOR MODULE NOT PERFORMED

• Verify if malfunction caused by initialization procedure.

• Has the initial setting been performed after replacing the DSC HU/CM?

|

Yes

|

Replace the instrument cluster, and perform the repair completion verification.

|

|

No

|

Perform the brake fluid pressure sensor initial setting, and perform the repair completion verification.

|

||

|

Repair completion verification

|

VERIFY THAT MALFUNCTION SYMPTOMS DO NOT RECUR AFTER REPAIR

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting.

Explain to the customer what has been repaired.

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the DSC HU/CM. (See DSC HU/CM REMOVAL/INSTALLATION [L.H.D. (US)].)

|