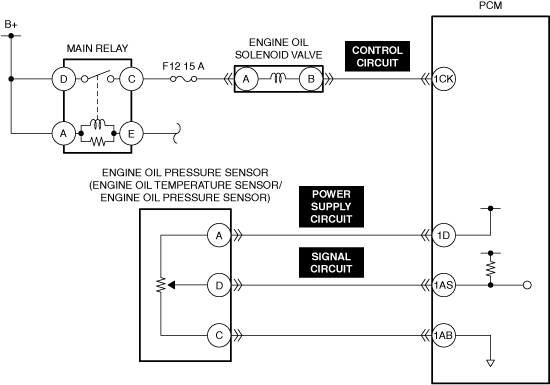

DTC P0524:00 [PCM (SKYACTIV-G (WITH CYLINDER DEACTIVATION (US)))]

DTC P0524:00 [PCM (SKYACTIV-G (WITH CYLINDER DEACTIVATION (US)))]

SM2565540

id0102t43397u4

Outline

|

System malfunction location |

Engine oil pressure too low |

||||

|---|---|---|---|---|---|

|

Detection condition

|

• If any of the following conditions is met under condition A or condition B:

|

||||

|

Fail-safe

|

Condition A:

• Restricts the upper limit of the engine speed.

Condition B:

• Inhibits the cylinder deactivation control.

|

||||

|

Possible cause

|

• Engine oil leakage

• Improper engine oil level

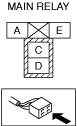

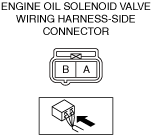

• Engine oil solenoid valve connector or terminals malfunction

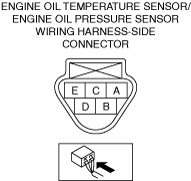

• Engine oil temperature sensor/engine oil pressure sensor connector or terminals malfunction

• PCM connector or terminals malfunction

• Short to ground in engine oil solenoid valve control circuit

• Short to ground in engine oil pressure sensor following circuit:

• Engine oil solenoid valve malfunction

• Engine oil pressure sensor malfunction

• Oil pump malfunction

• PCM malfunction

|

||||

|

|||||

|

|

||||

|

|||||

|

|||||

Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snapshot data.

|

—

|

Go to the next step.

|

|

2

|

VERIFY RELATED REPAIR INFORMATION OR SERVICE INFORMATION AVAILABILITY

• Verify related Service Bulletins, on-line repair information, or Service Information availability.

• Is any related Information available?

|

Yes

|

Perform repair or diagnosis according to the available information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECT ENGINE OIL LEAKAGE

• Start the engine.

• Verify that there is no engine oil leakage in the hydraulic circuit.

• Is there any leakage?

|

Yes

|

Repair or replace the malfunctioning location, then add genuine motor oil.

Perform the “ENGINE OIL DATA RESET” and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

4

|

INSPECT ENGINE OIL LEVEL

• Inspect the engine oil level. (See ENGINE OIL LEVEL INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].)

• Is the engine oil level sufficient?

|

Yes

|

Go to the next step.

|

|

No

|

Add genuine motor oil.

Perform the “ENGINE OIL DATA RESET” and perform the repair completion verification.

|

||

|

5

|

INSPECT ENGINE OIL SOLENOID VALVE CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (See CONNECTOR INSPECTION.)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

6

|

INSPECT ENGINE OIL TEMPERATURE SENSOR/ENGINE OIL PRESSURE SENSOR CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (See CONNECTOR INSPECTION.)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

7

|

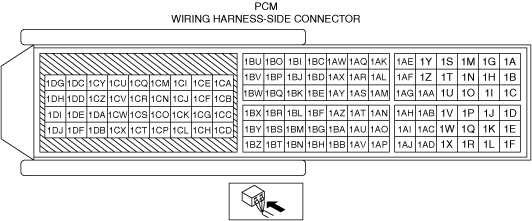

INSPECT PCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (See CONNECTOR INSPECTION.)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

8

|

INSPECT ENGINE OIL SOLENOID VALVE CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

9

|

INSPECT ENGINE OIL PRESSURE SENSOR POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (See CIRCUIT INSPECTION.)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

10

|

INSPECT ENGINE OIL SOLENOID VALVE FOR MALFUNCTION

• Inspect the applicable part. (See ENGINE OIL SOLENOID VALVE INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

11

|

INSPECT ENGINE OIL PRESSURE SENSOR FOR MALFUNCTION

• Inspect the applicable part. (See ENGINE OIL PRESSURE SENSOR INSPECTION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].)

• Is the part normal?

|

Yes

|

Replace the oil pump and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (See CLEARING DTC.)

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

• Perform the DTC inspection for the PCM. (See DTC INSPECTION.)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step. (See PCM REMOVAL/INSTALLATION [SKYACTIV-G (WITH CYLINDER DEACTIVATION (US))].)

|

|

No

|

Go to the next step.

|

||

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection. (See DTC INSPECTION.)

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|