STARTER INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))]

STARTER INSPECTION [SKYACTIV-G (WITHOUT CYLINDER DEACTIVATION (US))]

SM2565835

id0119u0800300

On-vehicle Inspection

1.Verify that the battery is fully charged. (See BATTERY INSPECTION [(US)].)

2.The starter is normal if it rotates smoothly and without any noise when the engine is cranked.

-

• If the starter does not operate, inspect the following:

-

― Remove the starter, and inspect the starter unit.― Inspect the related wiring harnesses, the ignition switch, and the starter interlock switch (MTX).― Verify any TCM DTCs to check whether there is a malfunction with the selector lever in determining the shift position (ATX). (See ON-BOARD DIAGNOSTIC SYSTEM DTC TABLE [TCM (ET6A-EL) (US)].)

-

No-load Test

1.Verify that the battery is fully charged. (See BATTERY INSPECTION [(US)].)

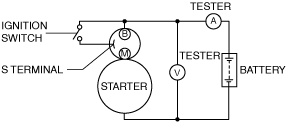

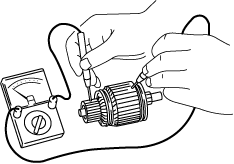

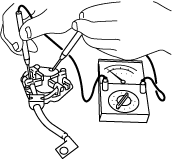

2.Connect the starter, battery, and a tester as shown in the figure.

am6xuw00002343

|

3.Operate the starter and verify that it rotates smoothly.

-

• If the starter does not rotate smoothly, inspect the starter unit.

4.Measure the voltage and current while the starter is operating.

-

• If not within specification, replace the starter.

-

Starter no-load test voltage

-

11 V

-

Starter no-load test current

-

SKYACTIV-G 2.0: 95 A or lessSKYACTIV-G 2.5: 90 A or less

Magnetic Switch Operation Inspection

Pull-out test

-

Note

-

• Depending on the battery charge condition, the starter motor pinion may rotate while in an extended state. This is due to current flowing to the starter motor through the pull-in coil to turn the starter motor, and does not indicate an abnormality.

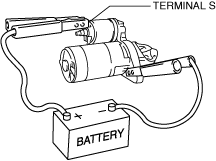

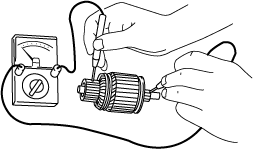

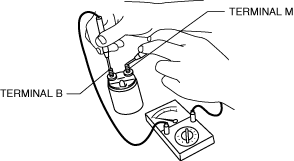

1.Verify that the starter motor pinion is extended while battery positive voltage is connected to terminal S and the starter body is grounded.

am6xuw00002344

|

-

• If the starter motor pinion is not extended, repair or replace the starter.

Return test

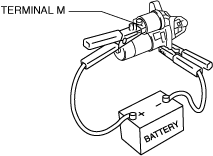

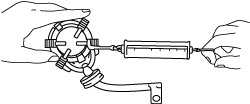

1.Disconnect the motor wire from terminal M.

2.Connect battery positive voltage to terminal M and ground the starter body.

am6xuw00002345

|

3.Pull out the drive pinion with a screwdriver. Verify that it returns to its original position when released.

-

• If it does not return, repair or replace the starter.

Pinion Gap Inspection

1.Pull out the drive pinion with the battery positive voltage connected to terminal S and the starter body grounded.

am6xuw00002344

|

-

Caution

-

• Applying power for more than 10 s can damage the starter. Do not apply power for more than 10 s.

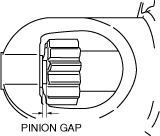

2.Measure the pinion gap while the drive pinion is extended.

am6zzw00002377

|

-

• If not as specified, adjust with an adjustment washer (between drive housing front cover and magnetic switch).

-

Starter pinion gap

-

0.5—2.0 mm {0.02—0.07 in}

Starter Inner Parts Inspection

Armature

1.Verify that there is no conductivity between the commutator and the core at each segment using a tester.

am6zzw00002378

|

-

• If there is conductivity, replace the armature.

2.Verify that there is no conductivity between the commutator and the shaft using a tester.

am6zzw00002379

|

-

• If there is conductivity, replace the armature.

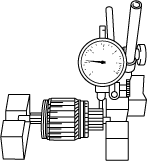

3.Place the armature on V‐blocks, and measure the runout using a dial indicator.

am6zzw00002380

|

-

• If not within specification, replace the armature.

-

Starter armature runout

-

0.1 mm {0.004 in} max.

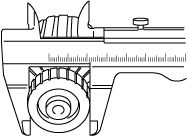

4.Measure the commutator diameter.

am6zzw00002381

|

-

• If not within the minimum specification, replace the armature.

-

Starter commutator diameter

-

Standard: 29.4 mm {1.16 in}Minimum: 28.8 mm {1.13 in}

5.Measure the segment groove depth of the commutator.

am6zzw00002382

|

-

• If not within the minimum specification, undercut the grooves to the standard depth.

-

Segment groove depth of starter commutator

-

Standard: 0.5 mm {0.02 in}Minimum: 0.2 mm {0.008 in}

Magnetic switch

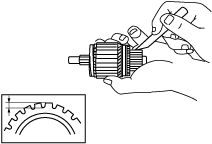

1.Inspect for conductivity between terminals S and M using a tester.

am6xuw00002346

|

-

• If there is no conductivity, replace the magnetic switch.

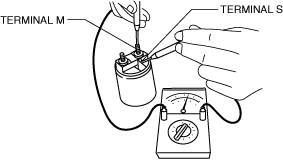

2.Inspect for conductivity between terminal S and the body using a tester.

am6xuw00002347

|

-

• If there is no conductivity, replace the magnetic switch.

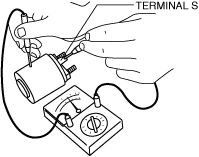

3.Verify that there is no conductivity between terminals M and B using a tester.

am6xuw00002348

|

-

• If there is conductivity, replace the magnetic switch.

Brush and brush holder

1.Verify that there is no conductivity between each insulated brush and plate using a tester.

am6zzw00002386

|

-

• If there is conductivity, replace the brush holder.

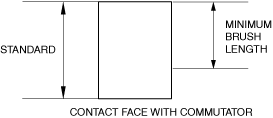

2.Measure the brush length.

ac5uuw00002441

|

-

• If any brush is worn almost to or beyond the minimum specification, replace all of the brushes.

-

Starter brush length

-

Standard: 12.3 mm {0.484 in}Minimum: 5.5 mm {0.22 in}

3.Measure the brush spring force using a spring balance.

am6zzw00002388

|

-

• If not within the minimum specification, replace the brush and brush holder component.

-

Starter brush spring force

-

Standard: 15.0—20.4 N {1.53—2.08 kgf, 3.38—4.58 lbf}Minimum: 2.75 N {0.280 kgf, 0.618 lbf}