OPERATION USING STEERING SWITCH NOT POSSIBLE

OPERATION USING STEERING SWITCH NOT POSSIBLE

SM2337309

id160300001300

Outline

|

Possible cause

|

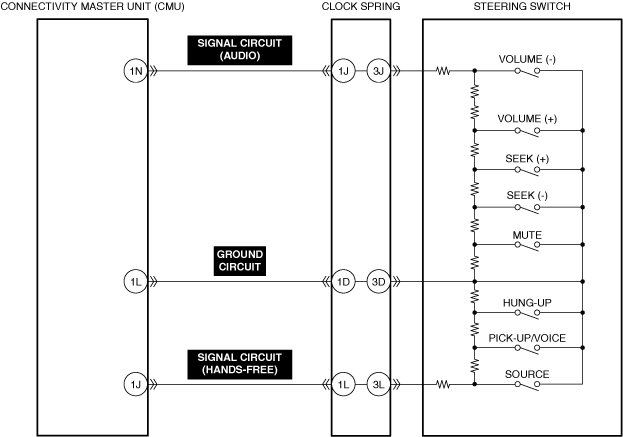

• Connector or terminal malfunction of the following parts:

• Short to power supply, short to ground, or open circuit in steering switch signal circuit

• Steering switch malfunction

• Clock spring malfunction

• Connectivity master unit (CMU) malfunction

|

|

|

|

|

|

|

|

|

Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

VERIFY ALL SYSTEM DTCs

• Perform the DTC inspection. (Refer to the [DTC INSPECTION] in the workshop manual)

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

2

|

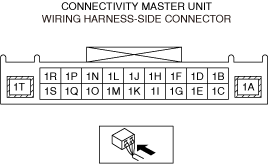

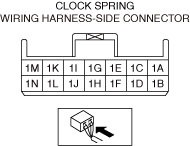

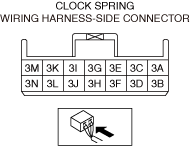

INSPECT STEERING SWITCH, CLOCK SPRING, AND CONNECTIVITY MASTER UNIT (CMU) CONNECTORS FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

3

|

INSPECT STEERING SWITCH SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY, SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the signal circuit for a short to power supply, short to ground, and an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

4

|

INSPECT STEERING SWITCH FOR MALFUNCTION

• Inspect the applicable part. (Refer to the [STEERING SWITCH INSPECTION] in the workshop manual)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

(Refer to the [STEERING SWITCH REMOVAL/INSTALLATION] in the workshop manual)

|

||

|

5

|

INSPECT CLOCK SPRING FOR MALFUNCTION

• Inspect the applicable part. (Refer to the [CLOCK SPRING INSPECTION] in the workshop manual)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

(Refer to the [CLOCK SPRING REMOVAL/INSTALLATION] in the workshop manual)

|

||

|

Repair completion verification

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

(Refer to the [CONTROLLER AREA NETWORK (CAN) MALFUNCTION DIAGNOSIS FLOW] in the workshop manual)

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction is not resolved, replace the connectivity master unit (CMU). (Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|