REPAIR-USE CONNECTOR REPLACEMENT PROCEDURE

REPAIR-USE CONNECTOR REPLACEMENT PROCEDURE

SM2334350

id000000003000

Wire Harness Cutting On Vehicle Side

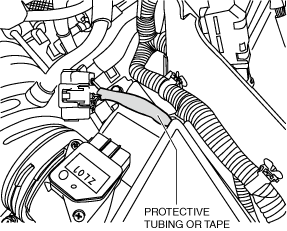

1.If tubing or tape is used to protect the connector wiring harness, cut into it being careful not cut or damage the wiring, and expose approx. 200 mm {7.84 in} of the wiring from the connector.

am6xuw00006203

|

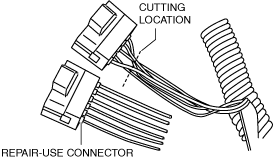

2.Cut the wiring harness once at the position near the connector so as to leave a long length of wiring harness on the vehicle side, align the length with the repair-use connector wiring harness, and then re-cut at the wiring harness on the vehicle side or the repair-use connector wiring harness at the appropriate position.

acmzzc00000415

|

-

Caution

-

• Cut longer in consideration of the amount of wiring harness length which will be soldered.• If the cut wiring harness length is different than the repair-use wiring harness length, the following problems may occur.

-

― If too short: Tension will be applied to the terminal, splice or connector resulting in an open circuit.― If too long: A short may occur due to pinching and wear of the extra length of wiring harness near the connector.

-

-

Note

-

• If several wiring harnesses are connected to the same connector, stagger the cut positions so that the repair positions do not overlap as shown in the figure to prevent thickening of the wiring harness after repair.

am6zzw00011195

am6zzw00011195

Cut Off the Insulation from the Wiring Harness on the Vehicle Side and the Repair-use Connector Wiring Harness

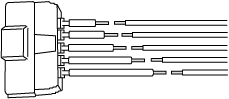

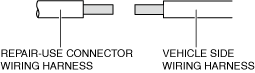

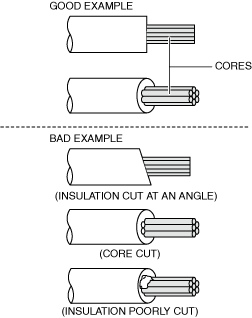

1.Strip off the insulation from the ends of the vehicle wiring harness and the repair-use connector wiring harness.

ac9uuw00009709

|

-

• For soldering repairs: 10—20 mm {0.40—0.78 in}• For repairs using crimp terminal: 6—7 mm {0.24—0.27 in}

-

Note

-

• If the wiring harness to be repaired is thick, core twisting can be facilitated by lengthening the amount of insulation cut.

-

Caution

-

• Do not damage or cut the cores of the wiring harnesses. After finishing the work, inspect the wiring harnesses for damage or cutting of the cores, and re-do the work if necessary.

amxzzw00003884

amxzzw00003884

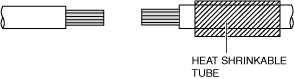

2.Depending on the thickness of the wiring harness which is being repaired, select an appropriate heat shrinkable tube, and before twisting the cores together, pass them through the heat shrinkable tube.

am6xuw00006207

|

|

|

Heat shrinkable tube |

Wiring size (exterior diameter) |

|

|---|---|---|---|

|

Before shrinking |

After shrinking |

||

|

Small

|

4 mm {0.2 in}

|

1 mm {0.04 in}

|

φ2 mm {0.08 in} or less

|

|

Large

|

8 mm {0.3 in}

|

2 mm {0.08 in}

|

φ2 mm {0.08 in} or more

|

-

Note

-

• If the exposed area of the core where the solder is applied is a shorter length of approx. 10 mm {0.39 in}, half the length ( 25 mm {0.98 in}) of the heat-shrinkable tubing can be cut and used because the total length of the heat-shrinkable tubing is 50 mm {2.0 in}.