REVERSE IDLER GEAR COMPONENT INSPECTION

REVERSE IDLER GEAR COMPONENT INSPECTION

SM2841719

id051500168400

Reverse idler gear inspection

1. Inspect the gears for damage, wear, or loss.

-

• If there is any malfunction, replace the reverse idler gear.

2.Inspect for damage and wear on the contact surface of the synchronizer ring.

-

• If there is any malfunction, replace the reverse idler gear.

Synchronizer ring inspection

1.Inspect the teeth of the synchronizer ring for damage, wear, or loss.

-

• If there is any malfunction, replace the synchronizer ring.

2.Inspect the taper surface for wear or loss.

-

• If there is any malfunction, replace the synchronizer ring.

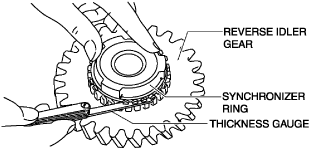

3.While holding the synchronizer ring and reverse idler gear with your fingers as shown in the figure, measure the clearance of the synchronizer ring and gear side surface around the entire circumference using a thickness gauge.

bc61um00000013

|

-

• If it is less than the minimum specification, replace the synchronizer ring.

-

Clearance between synchronizer ring and reverse idler gear side

-

Specification: 0.95 mm {0.037 in}Minimum: 0.49 mm {0.019 in}

Clutch hub component inspection

1.Inspect the clutch hub sleeve and clutch hub operation.

-

• If there is any malfunction, replace the malfunctioning part.

2.Inspect the spline for damage, wear or loss.

-

• If there is any malfunction, replace the malfunctioning part.

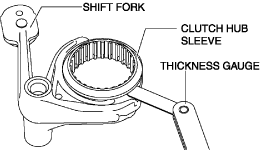

3. While holding the clutch hub sleeve and shift fork together with your hand as shown in the figure, measure the clearance between the shift fork and clutch hub sleeve groove using a thickness gauge.

bc61um00000014

|

-

• If it exceeds the maximum, replace the clutch hub sleeve and shift fork as a set.

-

Clearance between shift fork and clutch hub sleeve groove

-

Specification: 0.225 mm {0.00886 in}Maximum: 0.40 mm {0.016 in}