CONNECTING ROD CLEARANCE INSPECTION

CONNECTING ROD CLEARANCE INSPECTION

SM2841624

id011000507600

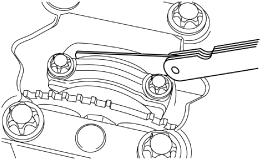

1.Measure the side clearance at the large end of the connecting rod using a feeler gauge.

bp31je00000148

|

-

• If it exceeds the maximum specification, replace the connecting rod or crankshaft.

-

Standard side clearance at the large end of connecting rod

-

0.14—0.36 mm {0.006—0.014 in}

-

Maximum side clearance at the large end of connecting rod

-

0.465 mm {0.0183 in}

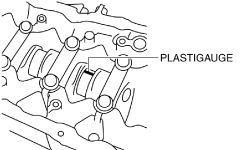

2.Measure the oil clearance at the large end of the connecting rod using the following procedure:

- (1)Cut the plastigauge as wide as the connecting rod bearing width, place it parallel to the crankshaft, avoiding the oil hole.

-

bpe2ue00000093

bpe2ue00000093

- (2)Install the lower connecting rod bearing and connecting rod cap. (See CYLINDER BLOCK ASSEMBLY (I).)

- (3)Remove the connecting rod cap. (See CYLINDER BLOCK DISASSEMBLY (II).)

- (4)Measure the oil clearance at the large end of the connecting rod.

-

-

• If it exceeds the maximum specification, replace the bearing or grind the crank pin and use oversize bearings so that the specified clearance is obtained.

-

Standard bearing oil clearance at the large end of the connecting rod

-

0.026—0.052 mm {0.0011—0.0020 in}

-

Maximum bearing oil clearance at the large end of the connecting rod

-

0.10 mm {0.0039 in}

-

-

Connecting rod bearing size

-

STD: 1.502—1.519 mm {0.05914—0.05980 in}OS 0.25: 1.628—1.631 mm {0.06410—0.06421 in}OS 0.50: 1.753—1.756 mm {0.06902—0.06913 in}