CYLINDER HEAD ASSEMBLY (II)

CYLINDER HEAD ASSEMBLY (II)

SM2841695

id011000504400

Replacement Part

|

Cylinder head gasket

Quantity: 1

Location of use: Cylinder head

|

O-ring

Quantity: 4

Location of use: OCV oil filter

|

Oil and Chemical Type

|

Engine oil

Type: Recommended oil

|

Gear oil

Type: SAE 90 gear oil or equivalent

|

Sealant

Type: LOCTITE 962T or equivalent

|

|

Silicone sealant

Type: TB1217D or equivalent

|

—

|

—

|

-

Caution

-

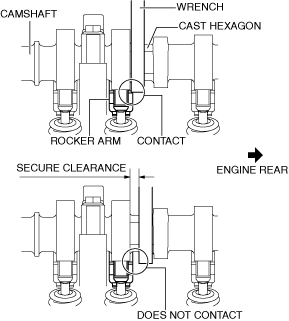

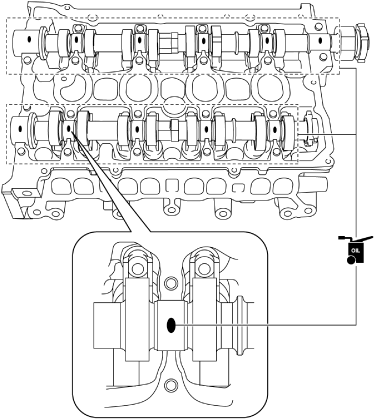

• If the camshaft is rotated with the timing chain removed and the piston at the top dead center position, the valve may contact the piston and the engine could be damaged. When rotating the camshaft with the timing chain removed, rotate it after lowering the piston from the top dead center position.• When rotating the camshaft using a wrench on the cast hexagon, the wrench may contact the rocker arm and damage the rocker arm. To prevent damage to the rocker arm when holding the camshaft on the cast hexagon, use a wrench on the rear side of the engine as shown in the figure to secure a clearance between the cam.

am3uuw00008968

am3uuw00008968

-

Note

-

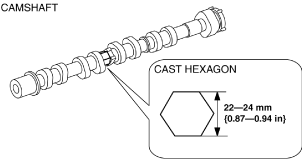

• Width at the cast hexagon of the camshaft is 22—24 mm {0.87—0.94 in}.

bpe7ze00000032

bpe7ze00000032

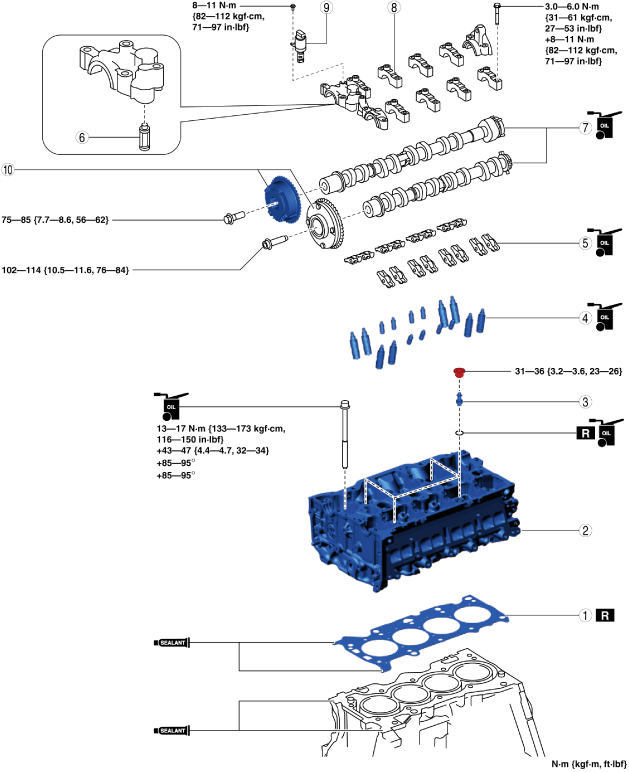

1.Assemble in the order indicated in the table.

bp28ue00000004

|

|

1

|

Cylinder head gasket

|

|

2

|

Cylinder head

(See Cylinder Head Assembly Note.)

|

|

3

|

OCV oil filter

(See OCV Oil Filter Assembly Note.)

|

|

4

|

HLA, Switchable HLA

|

|

5

|

Rocker arm

(See Rocker Arm Assembly Note.)

|

|

6

|

OCV oil filter

|

|

7

|

Camshaft

(See Camshaft Assembly Note.)

|

|

8

|

Camshaft cap

(See Camshaft Assembly Note.)

|

|

9

|

OCV for hydraulic variable valve timing system

|

|

10

|

Electric variable valve timing actuator, hydraulic variable valve timing actuator

|

Cylinder Head Assembly Note

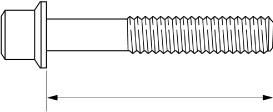

1.Measure the length of the cylinder head bolt.

-

• If it exceeds the maximum specification, replace the cylinder head bolt.

bpe8ze00000047

|

-

Standard cylinder head bolt length

-

145.2—145.8 mm {5.717—5.740 in}

-

Maximum cylinder head bolt length

-

146.5 mm {5.768 in}

2.When a cylinder head bolt is reused, apply engine oil to any part of the following:

-

• Bolt seating surface• Cylinder head seating surface

-

Caution

-

• Completely remove oil, dirt, and sealant adhering to the cylinder head gasket contacting surfaces. Otherwise, a sealing malfunction may occur.

3.Completely remove any oil, dirt, and sealant adhering to the cylinder block.

-

Caution

-

• Be aware of the following points, otherwise a sealing malfunction may occur due to hardening of the sealant.

-

― Set cylinder head on cylinder block within 10 min after silicone sealant is applied― After setting cylinder head, tighten cylinder head bolts immediately

-

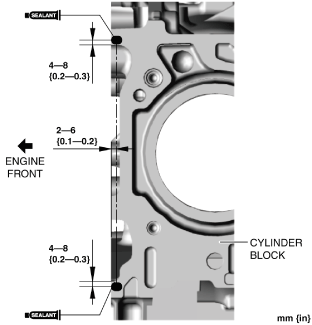

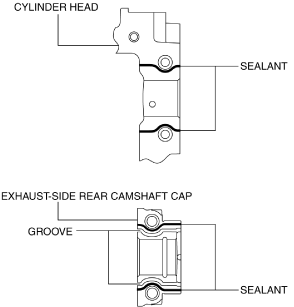

4.Apply silicone sealant (TB1217D or equivalent) to the areas shown in the figure.

btstze00000022

|

-

Silicone sealant application diameter

-

5—10 mm {0.2—0.3 in}

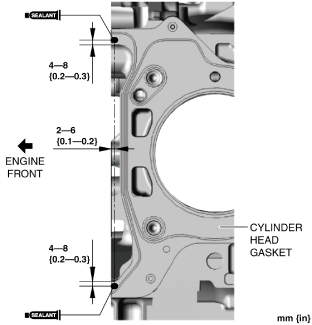

5.Install a new cylinder head gasket to the cylinder block.

6.Apply silicone sealant (TB1217D or equivalent) to the areas shown in the figure.

btstze00000023

|

-

Silicone sealant application diameter

-

5—10 mm {0.2—0.3 in}

7.Set the cylinder head on the cylinder block.

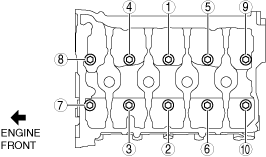

8.Tighten the cylinder head bolts in the order shown in the following four steps.

am3uuw00008818

|

-

Tightening procedure

-

Step 1: 13—17 N·m {133—173 kgf·cm, 116—150 in·lbf}Step 2: 43—47 N·m {4.4—4.7 kgf·m, 32—34 ft·lbf}Step 3: 85—95°Step 4: 85—95°

OCV Oil Filter Assembly Note

1.Install new O-rings to the OCV oil filters.

2.Apply clean engine oil to the o-ring of the OCV oil filter.

3.Install the OCV oil filters.

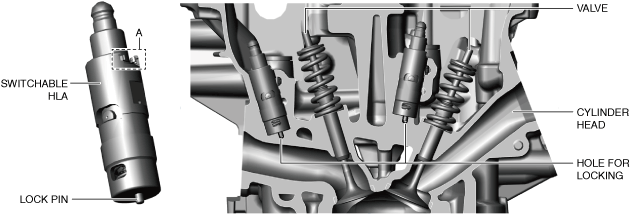

HLA, Switchable HLA Assembly Note

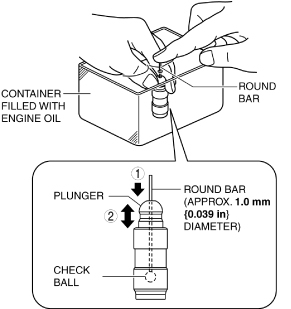

1.Perform air bleeding of the HLA and switchable HLA using the following procedure.

- (1)Put the HLA and switchable HLA in a container filled with engine oil.

-

-

Caution

-

• Do not insert the round bar firmly because the check ball spring force is extremely weak.

-

- (2)While lightly pressing the check ball using a round bar ( approx. 1.0 mm {0.039 in} diameter), bleed air by moving the plunger up and down.

-

bpe8ze00000012

bpe8ze00000012

- (3)Press the end of the plunger in the oil and verify that there is no rebounding feel.

-

-

• If rebounding feel cannot be eliminated, replace the HLA and switchable HLA.

-

2.Assemble the HLAs to their original positions.

-

Caution

-

• Assemble the switchable HLAs correctly. Otherwise, the engine could be damaged.

3.Assemble the switchable HLAs to their original positions using the following procedure.

- (1)Insert the switchable HLA into the cylinder head.

-

-

Note

-

• Assemble the lock pin of the switchable HLA so that it is inserted into the holes for locking on the cylinder head side.• If area A in the figure is inserted into the switchable HLA with it facing the valve, it will facilitate insertion of the lock pin of the switchable HLA into the hole for locking on the cylinder head side.

bp27ze00000002

bp27ze00000002 -

- (2)Rotate the switchable HLA and verify that the lock pin of the switchable HLA is securely inserted into the hole for locking on the cylinder head side.

-

-

Note

-

• When the lock pin of the switchable HLA is securely inserted into the hole for locking on the cylinder head side, the switchable HLA cannot be rotated 90 degrees or more.

-

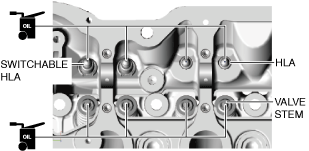

Rocker Arm Assembly Note

1.Apply engine oil to the HLAs, switchable HLAs and the end of the valve stems.

ac5wzw00010868

|

2.Install the rocker arms to their original positions as before removal.

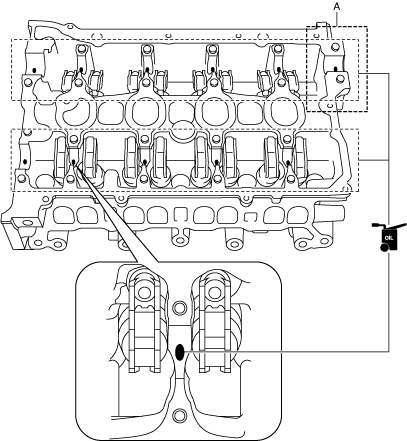

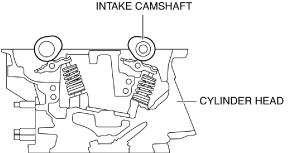

Camshaft Assembly Note

1.Apply SAE 90 gear oil or equivalent, or engine oil to the positions shown in the figure.

-

Caution

-

• Apply 0.05 ml {0.05 cc, 0.003 in 3} or less of oil to area A in the figure.

am2zzw00011199

|

2.Apply gear oil (SAE 90 or equivalent) or engine oil to the thrust surface (both surfaces front and back) of the front journal on each camshaft.

-

Caution

-

• Be careful not to let oil adheres the engine front cover installation surface. If oil adheres to the engine front cover installation surface, a sealing malfunction may occur when the engine front cover is installed.• If oil adheres to the engine front cover installation surface, remove any oil completely.

-

Note

-

• If oil is applied to the front camshaft cap, oil should not be applied to the thrust surface of the front journal.

3.As shown in the figure, align the cam position of cylinder No.1 around top dead center (TDC) and place the camshafts on the cylinder head.

btstze00000024

|

4.Apply SAE 90 gear oil or equivalent, or engine oil to the central area of each journal on the camshaft.

bpe1ze00000011

|

5.Apply SAE 90 gear oil or equivalent, or engine oil to the thrust surface of the front camshaft cap.

-

Caution

-

• Be careful not to let oil adheres the engine front cover installation surface. If oil adheres to the engine front cover installation surface, a sealing malfunction may occur when the engine front cover is installed.• If oil adheres to the engine front cover installation surface, remove any oil completely.

-

Note

-

• If oil is applied to the front journal thrust surface of each camshaft, oil should not be applied to the front camshaft cap.

6.Apply sealant (LOCTITE 962T or equivalent) to the rear camshaft cap installation area on the exhaust side of the cylinder head or the rear camshaft cap on the exhaust side.

-

Note

-

• To prevent engine oil leakage, apply sealant to the rear camshaft cap installation area on the exhaust side of the cylinder head or the rear camshaft cap on the exhaust side, and seal the journal.

bpe8ze00000015

|

-

Caution

-

• Do not spill sealant on the journal.

-

Sealant bead width

-

1—3 mm {0.04—0.11 in}

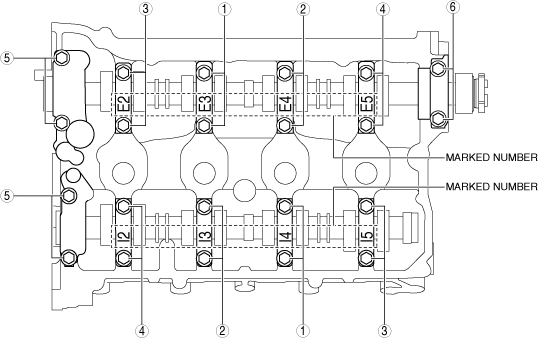

7.Install the camshaft caps in the marked number order, and temporarily tighten the camshaft cap installation bolts in two or three passes evenly.

8.Tighten the camshaft cap installation bolts in two steps in the order shown in the figure.

am3uuw00008996

|

-

Tightening torque

-

Step 1: 3.0—6.0 N·m {31—61 kgf·cm, 27—53 in·lbf}Step 2: 8—11 N·m {82—112 kgf·cm, 71—97 in·lbf}

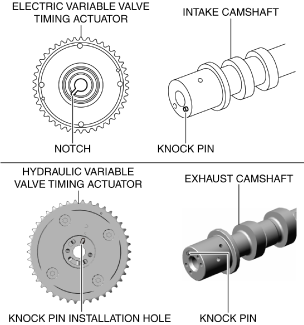

Electric Variable Valve Timing Actuator, Hydraulic Variable Valve Timing Actuator Assembly Note

1.Align the knock pin on the end of the camshaft with the notch on the actuator (intake side) or knock pin installation hole (exhaust side), then install the actuator to the camshaft.

btstze00000025

|

2.Hold the camshaft using a wrench on the cast hexagon, and tighten the actuator installation bolt.

-

Tightening torque

-

Electric variable valve timing actuator (intake side): 102—114 N·m {10.5—11.6 kgf·m, 76—84 ft·lbf}Hydraulic variable valve timing actuator (exhaust side): 75—85 N·m {7.7—8.6 kgf·m, 56—62 ft·lbf}