PISTON INSPECTION

PISTON INSPECTION

SM2841605

id011000502100

-

Caution

-

• If the piston is replaced, replace the piston, piston pin, and the snap ring as a single component.

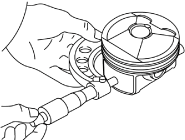

1.Measure the piston outer diameter using the micrometer. The measurement position is 8.0 mm {0.31 in} from the lower end of the piston (area with no coating on the piston skirt) and in the thrust direction.

bpe1ze00000097

|

-

• If it is not within the specification, replace the piston.

-

Standard piston outer diameter

-

88.965—88.995 mm {3.5026—3.5037 in}

2.Measure the cylinder bore diameter. (See CYLINDER BLOCK INSPECTION.)

3.Calculate the cylinder-to-piston clearance from the cylinder bore diameter and the piston outer diameter.

-

• If the clearance exceeds the maximum specification, replace the piston or cylinder block.

-

Standard clearance between piston and cylinder

-

0.025—0.045 mm {0.0010—0.0017 in}

-

Maximum clearance between piston and cylinder

-

0.066 mm {0.0026 in}

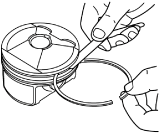

4.Measure the piston-to-ring groove clearance along the perimeter using a feeler gauge. For the O-ring, measure the clearance with the O-ring assembled to the piston.

bpe1ze00000098

|

-

• If the clearance exceeds the maximum specification, replace the piston or piston ring.

-

Standard clearance between piston ring and ring groove

-

Top: 0.04—0.08 mm {0.002—0.003 in}Second: 0.03—0.07 mm {0.0012—0.0027 in}Oil: 0.04—0.12 mm {0.002—0.004 in}

-

Maximum clearance between piston ring and ring groove

-

Top: 0.12 mm {0.0047 in}Second: 0.10 mm {0.0039 in}Oil: 0.17 mm {0.0067 in}